Zero Liquid Discharge Plants (ZLD)

Why Zero Liquid Discharge (ZLD)?

- Environmental regulation on discharge of specific solutes (salt, toxic elements, nitrate nitrate‐nitrite nitrite etc)

- Water scarcity/water stress growing world‐wide along with still negligible rate of waste water recycling

- Economics: recycled water becomes more affordable as the water supply from conventional sources becomes more expensive;

- Growing social responsibility and education towards awareness of environmental issues

- While ZLD cost is high in most cases, it might be a more economic solution when waste needs to be transported in large volumes over long distances

Limitations of ZLD

- Very high cost (both CAPEX and OPEX)

- Custom‐design on case‐to‐case basis

- Difficulties to deal with complex streams

Conventional Thermal ZLD Technology

- The conventional ZLD is based on evaporation and crystallization operations

- Evaporation usually aims at>90% water recovery

- Crystallization may achieve 100% recovery

- Solids can be further dewatered on a filter‐press for landfill

- Latent heat of Evaporation is partly recovered

- Operational and capital costs are still very high due to high energy consumption (20‐40 kWh/m3 vs. 2‐3 kWh/m3 in desalination), use of chemicals and expensive corrosion‐resistant materials.

Evaporator

Evaporation is a unit operation that separates a liquid from solids by means of heat transfer via vaporization or boiling. The purpose of evaporation is to concentrate a solution of a non volatile solute (i.e., solids) and a solvent (i.e., liquid), which is typically water. Water is removed from a solution by boiling the liquor in an evaporator and withdrawing the vapour. Evaporation occur in three steps:- 1- Pre-heating of a solution prior to evaporation, 2- Removal of water (solvent) as vapour by steam heating, 3- Condensing the vapour removed.

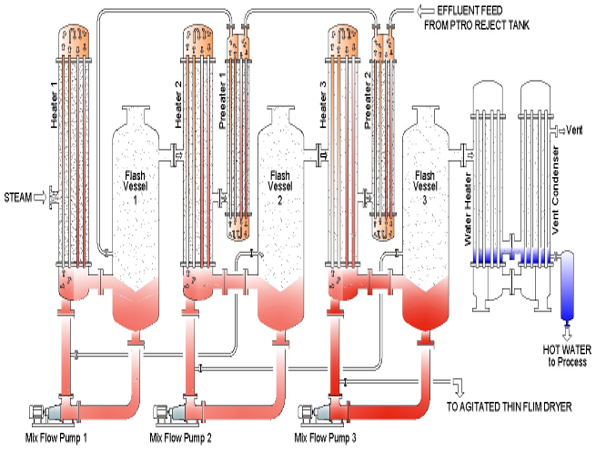

Multiple Effect Evaporation remains one of the popular methods used for the concentration of aqueous solutions. The multiple-effect configuration combines two or more evaporator bodies to conserve steam, which is condensed in the first-effect heat exchanger only. Water evaporated in the first-effect vapor body is condensed in the second-effect heat exchanger, which provides energy for evaporation in the second-effect vapor body (and so on for additional effects). Vapor from the last effect flows to a condenser. The last-effect vapor body is maintained at a high vacuum with a steam-jet air ejector or mechanical vacuum pump. The driving force is the pressure drop from the first to the last effect.

For the same overall pressure differential and process conditions, the evaporator with more effects will require less steam. The evaporation in each effect will be approximately 0.7 to 0.9 Kg for each Kg of steam condensed in the first-effect heat exchanger. For the same evaporation rate, a five-effect evaporator will require about 25% of the steam required for a single-effect evaporator. In actual practice, the steam economy can vary widely because of differences in feed temperature and other energy requirements such as heats of dilution and crystallization.

The number of effects is limited by the total available temperature difference between the plant steam and the cooling water temperature. Process liquors with high boiling point elevations typically operate with fewer effects.

A multiple-effect evaporator is divided in to three category on the basis of feed direction:- 1- Forward feed multi effect evaporator, 2-Backword Feed multi effect evaporator, 3- Mixed feed multi effect evaporator. It is also categorised as Raising Film Evaporator, Falling Film Evaporator, Forced Circulation Evaporator and Agitated Thin Film Evaporator

Crystallization

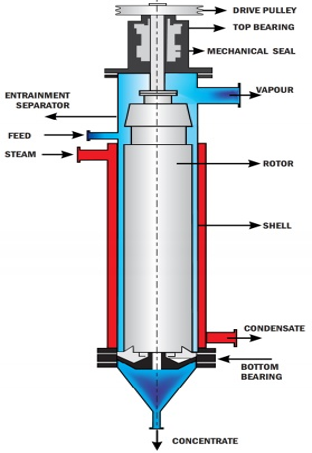

Due to its inherent design features, it is ideal for thermal treatment of solutions and heat sensitive products, where reduced operating temperatures and vacuum operating pressures are desirable. The typical Agitated Thin Film Evaporator consists of a tubular heat transfer area with an external heating jacket and a fast-revolving, inner rotor with flexible or rigid wiper elements. The driving speed is adapted to the product being handled, its particular specifications and task.

The feed product is evenly distributed by the rotor and its wipers over the heating surface, forming a thin liquid film of uniform thickness. Highly turbulent swirls are produced at the tip of the rotor blades and wipers with intensive mixing and agitation of the product, as it comes into contact with the heating surface. This assures excellent heat transfer combined with constant renewal of the product film and provides an even heating and short residence time of the product through the heated zone

We offer Customised solutions based on the client’s requirement. Entire Recycle Plant combined with ZLD can be offered in single package