High Rate Solid Contact Classifiers (HRSCC)

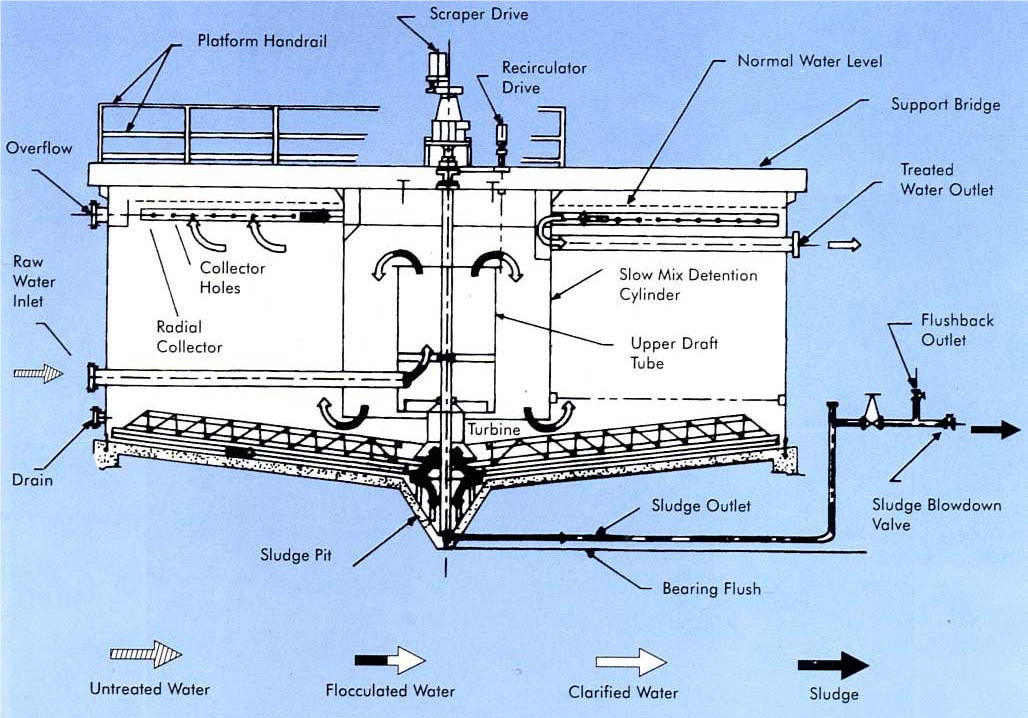

Flocculation and Clarification Combined in a Single Tank Reactor Clarifier solids contact units are designed and built to provide the most economical solution to precipitation and clarification requirements. The simple design provides for coagulation, flocculation, solids recirculation, clarification and positive sludge removal in a single basin. This eliminates the need for multiple tanks and additional pipework.

Principles of Operation

The raw water is first received in the Clarifier. The inlet water enters the flocculation zone and rises to the top and in the process the turbulence in the water is removed to a greater extent enabling the suspended solids to settle down. Chemicals shall be dosed to aid flocculation and coagulation which helps in settling the flocs faster.

Reactor Clarifier solids contact units combine slow turbine speeds and high volume internal recirculation to promote mixing, flocculation and solids-contact. The recirculation system is designed to promote particle growth and improve the removal of suspended solids. As influent enters the recirculation drum it is pumped upwards by a large diameter slow-speed turbine, where it comes into contact with a large volume of dense floc from previously precipitated solids (6 to 15 times the maximum influent rate is recirculated to increase solids contact with the new incoming feed). The resulting effluent is passed under the reaction cone to the clarification zone, with the heaviest particles settling to the floor. These are then raked to the centre for recirculation or discharge.

Salient features of High Rates Solid Contact Clarifier over Conventional Clariflocculator

High Rate Solids Contact Clarifier |

Clariflocculator |

|---|---|

| No External flash mixer required | External flash mixer is necessary. |

| Very high overflow rates achieved as a result of high flocculation zone concentration. | Low overflow rates resulting in high surface area requirements. |

| Internal sludge recirculation ensures high floc zone conc. at very low power consumption and without any additional equipments. | External circulation may be provided but results in high power consumption for pumps and additional equipments. |

| Reactivator can be specifically used for colloidal silica reduction. | Colloidal silica reduction (if any) is only incidental. |

| Very high process flexibility available just by changing the recirculator speed. | No process flexibility possible. |

| Sludge scraper blades cover full diameter ensuring quick sludge removal. | Only half scraping is available because of traction drive mechanism. |

| Complete utilization of chemicals due to continuous sludge recirculation. | Added chemicals are wasted as a result of no circulation of sludge resulting in at least 10% – 25% extra chemicals. |

| Can be used as lime softening in future if required without any modification. | Cannot be used for lime softening. |

| Negligible effect on overflow clarity as a result of temp. variation in raw water. | Appreciable effect on over flow clarity as a result of temperature variation. |

| Under flow sludge consistency is usually in the range of 3-4 % sludge (w/v) thereby reducing the water loss. | Under flow sludge consistency is usually in the range of 1-2% sludge (w/v). |