Ion Exchange Resin

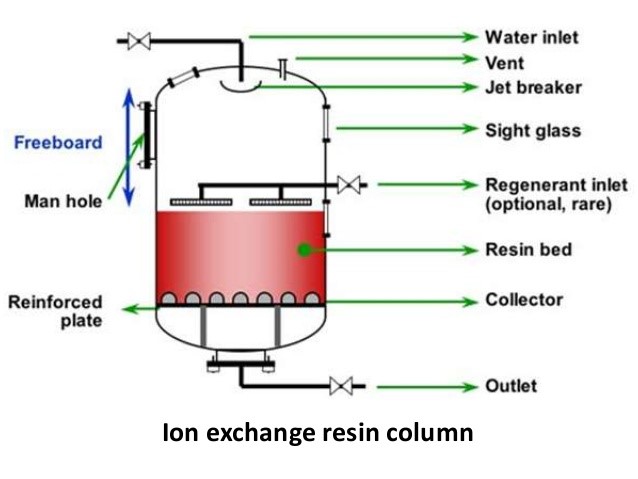

An Ion Exchange Resin is a resin or Polymer that acts as a medium for Ion Exchange. It is an insoluble matrix (or support structure) normally in the form of small (0.25–0.5 mm radius) microbeads, usually white or yellowish, fabricated from an organic polymer substrate. The beads are typically porous, providing a large surface area on and inside them. The trapping of ions occurs along with the accompanying release of other ions, and thus the process is called Ion Exchange. There are multiple types of ion-exchange resin. Most commercial resins are made of Polysterene Sulfonate

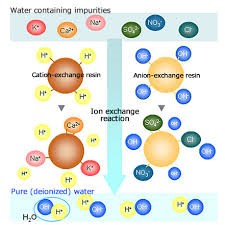

Ion–exchange resins are widely used in different Separation, Purification, and Decontamination processes. The most common examples are Water Softening and Water Purification to produce deionized water. These resins are composed of organic polymer chains that have charged functional groups built into the resin bead. Cation resin has a negative functional group and therefore attracts positively charged ions and Anions resins have positive functional group and therefore attracts negative charged ions. Specialised ion exchange resins are also known such as chelating resins